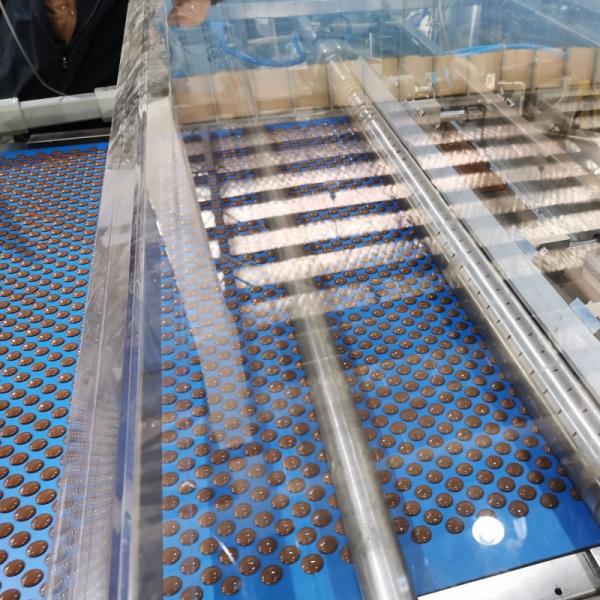

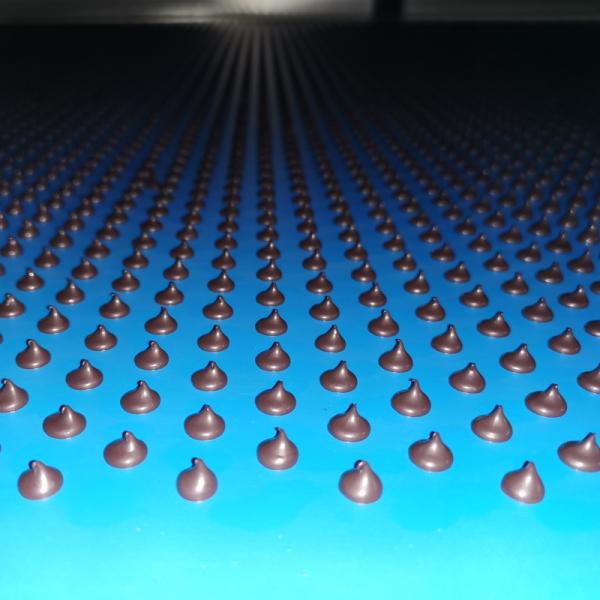

NJ Machinery® Rotary/Roller Type Chocolate Chips Depositor allows the depositing of chocolate and chocolate compound drops and chips in a variety of shapes and weights, ranging from 0.1 to 5 grams. These types of products are ideal for industrial supply and subsequent melting, for decorating and for use in other products, especially cookies and ice creams.

The chocolate chips depositing line includes a jacketed rotary drum equipped with temperature control and a moveable chocolate feeding system, with build in vibration sieve and chocolate feeding pump. The chocolate chips depositing line also includes a vibration table for enabling diverse drops shapes. The chocolate chips and drops are forwarded into cooling tunnel immediately after deposit.

Compared with traditional piston type chocolate chips depositor, the features of rotation type chocolate chips depositor are

-Easy Operate

-Simple Structure Easy Cleaning

-High Capacity

-Low Cost

Technical Parameters

Model | Belt Width(mm) | Line Speed(m/min) | Tunnel Temp.(℃) | Total Power(kW | Weight(kg | Overall Size(mm) |

CD600 | 600 | 0-10 | 0-15 | 19 | 2500 | 20000*950*1300 |

CD800 | 800 | 0-10 | 0-15 | 22 | 2800 | 24000*1150*1300 |

CD1000 | 1000 | 0-10 | 0-15 | 26 | 3500 | 30000*1350*1300 |

CD1200 | 1200 | 0-10 | 0-15 | 31 | 4800 | 35000*1550*2010 |

CD1500 | 1500 | 0-10 | 0-15 | 40 | 5800 | 40000*1850*2010 |

CD1800 | 1800 | 0-10 | 0-15 | 67 | 7600 | 40000*2150*2010 |

Features

-Continously Production

-Easy Cleaning

-Easy Change-Over

-Full Stainless Steel Construction

-Optional Cooling Bed to Shorten Tunnel Length

-Depositing Drum and Cooling Tunnel Separate Design

Chocolate Depositing Machine| Chocolate Chips Depositor| Chocolate Flake Depositing Machine| Chocolate Chips Depositing Line | Chocolate Drops Depositing Machine | Chocolate Making Machine